Guide to Wire 208 Volt Single Phase

Ever wondered if you can tackle wiring a 208-volt single-phase circuit on your own?

It might sound complex, but with a clear guide and the right approach, it’s a skill within your grasp. This essential capability can save you time and money, whether you’re setting up a new workshop, installing machinery, or just keen on understanding electrical systems.

With patience and the right tools, you’ll discover that mastering the intricacies of 208V single-phase wiring is entirely achievable.

Well, we’ll be going over:

- What are the foundational concepts you need to grasp about 208-volt single-phase wiring?

- Which tools are indispensable for safely and efficiently wiring a 208-volt single-phase circuit?

- What safety measures must you strictly adhere to while working on your wiring project?

Let’s dive in.

Contents

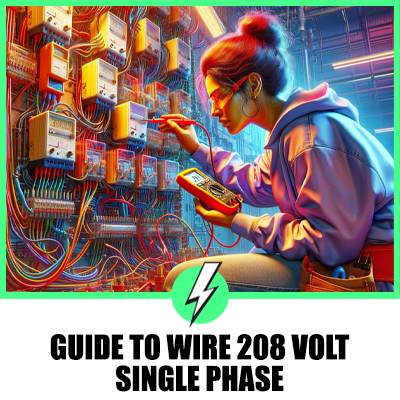

Understanding 208-Volt Single-Phase Wiring

When you’re diving into the task of wiring a 208-volt single-phase circuit, knowing the basics is crucial. This type of circuit is commonly used in both residential and commercial settings for powering heavy-duty appliances or equipment.

Unlike the more common 120-volt circuits, a 208-volt setup can deliver more power while maintaining efficiency.

Firstly, you need to understand that a single-phase supply comes from two hot wires. In a 208-volt system, these wires carry a voltage that, when measured across them, totals to 208 volts.

This is different from the three-phase power supply, which is used in larger commercial or industrial facilities.

For home workshops or small businesses, mastering 208-volt single-phase wiring opens up a world of possibilities for running heavy-duty tools and machinery without the need for costly transformations.

Safety cannot be overstated — always ensure the power is off before you start working on any wiring project. Use a multimeter to verify that the power is indeed off. You’ll also need to be familiar with your local electrical codes to ensure compliance.

Tools Needed for the Job

Before you dive into wiring a 208-volt single-phase circuit, it’s crucial to have the right tools at your disposal. Preparing with the necessary equipment ensures a smoother, safer workflow and helps prevent any unnecessary interruptions.

Firstly, a multimeter is indispensable for verifying the absence of power in the circuit before you begin. It’s your go-to for ensuring safety throughout the project.

Alongside, wire strippers and crimping tools are essential for preparing wires for secure connections.

Don’t forget screwdrivers and adjustable wrenches, as they will be your allies in loosening and securing connections throughout the installation process. For cutting wires to the correct length, a cable cutter is necessary to achieve clean, precise cuts.

Moreover, insulating tape and cable ties play a critical role in organising and protecting your wiring, preventing short circuits and ensuring a neat, professional result.

Having a non-contact voltage tester on hand offers an extra layer of safety, allowing you to double-check for unexpected live wires.

Equipping yourself with these tools not only streamlines the job but also elevates the level of safety and efficiency in tackling your 208-volt single-phase wiring project.

Safety Precautions to Keep in Mind

When embarking on wiring a 208-volt single-phase circuit, your safety should always come first.

Electricity is dangerous, and mishandling it can lead to severe injuries or even fatalities. Therefore, it’s crucial to follow these safety precautions closely.

Firstly, always ensure the power supply is turned off at the breaker box before beginning any work.

It’s an essential step that prevents unexpected electrical shocks. Use a non-contact voltage tester after turning off the power to double-check that the circuit is indeed dead.

Wearing the right personal protective equipment (PPE) can’t be overstated. This includes:

- Insulated gloves

- Safety goggles

- Flame-resistant clothing

Moreover, never work alone. Having someone around in case of an emergency can be a lifesaver. Lastly, be aware of your surroundings. Water and electricity are a deadly combination, so keep your work area dry and avoid working in wet conditions.

Remember, taking these safety measures not only protects you but also ensures the safety of those around the wiring project.

Step-by-Step Guide to Wiring a 208V Single-Phase Circuit

Wiring a 208V single-phase circuit might seem daunting, but with the right tools and safety measures, you can tackle this task with confidence.

Firstly, ensure the power is off at the breaker box to avoid any electrical hazards. A non-contact voltage tester can help confirm this.

Your safety gear, including insulated gloves and safety goggles, is non-negotiable.

Begin by selecting the appropriate wire size, crucial for the efficiency and safety of the circuit. Typically, for a 208V single-phase, a 12-gauge wire is suitable for up to 20 amps.

Use your wire strippers to carefully strip the insulation from the wires, exposing the amount needed to connect to the terminal screws effectively.

Tighten the terminal screws securely to ensure a solid connection. Inadequate connections can lead to electrical fires or equipment failure.

After you’ve connected the wires, double-check each connection with a multimeter to ensure there’re no short circuits.

Remember, at any sign of trouble or uncertainty, consulting with a professional electrician is not just advisable; it’s essential to ensure the safety and functionality of your 208V single-phase circuit.

Testing and Troubleshooting the Circuit

After wiring your 208V single-phase circuit, testing and troubleshooting are critical to ensure everything is in perfect order. Begin by using a multimeter set to measure voltage.

Carefully attach the meter probes to the circuit- the black to ground or neutral, and the red to the hot wire. A correct installation should read close to 208 volts. Any significant deviation signals a problem that must be addressed promptly.

If the voltage isn’t accurate, re-examine your connections. Loose or corroded connections often cause discrepancies. Ensure all terminals are tightened securely and no wires are frayed or damaged.

Remember, safety is paramount. Always make sure the power is off before touching any wires.

Should issues persist even after checking the connections and confirming the voltage, it might be time to consult with a professional electrician.

Sometimes, circuit problems stem from issues within the breaker box itself or from an external power supply inconsistency. An expert can diagnose and rectify these issues, ensuring your 208V single-phase circuit functions safely and efficiently.

Conclusion

Wiring a 208V single-phase circuit correctly is crucial for both performance and safety. Remember, after you’ve completed the wiring, the job isn’t quite finished.

You’ll need to test and troubleshoot the circuit meticulously using a multimeter to ensure everything is working as it should.

Should you encounter any discrepancies in voltage readings or any other issues, it’s vital to re-examine your connections and ensure all terminals are secure. In cases where problems persist, don’t hesitate to call in a professional electrician.

Their expertise can help identify and solve any underlying issues with your breaker box or external power supply. By taking these steps, you’ll guarantee that your circuit is not only efficient but also operates safely.