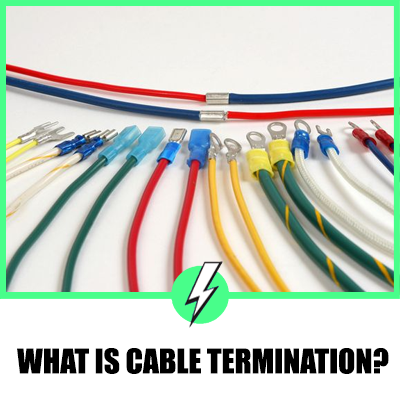

What Is Cable Termination?

If you terminate a cable, does it mean to discard the cable because it’s not fit for purpose?

The termination of cables does not mean it is not fit for purpose. Terminating a cable is when you need to make a connection to the wires or fibre optics coming from the cable. When you fit a simple plug, you terminate the cables by placing the cable into the plug and making the connections.

Contents

How is cable termination done?

It’s a simple process. You snip off the insulation from the end of the cable to reveal the live, neutral and earth wired, revolving around 11 mm of insulation exposing the copper wires.

You can then place each wire in the terminal and screw it down tight to make a good connection. You can also use Wago connectors to slide the exposed 11 mm copper wire into the Wago and then push the lever down to lock the wire in place.

Both are methods of termination that are used daily by electricians.

Why is cable termination required?

If cables were not terminated, you would have wires connected to appliances in their raw form, increasing the possibility of electrocution.

Terminating the end of cables is essential for good connections, be it with electricity or fibre cables.

Overhead and underground cables are terminated with crimps. The steel or copper Ferrule is placed over the cable ends, and pressure is applied to make an unbreakable connection between the two cables.

How do I prepare for a cable termination?

Strip back the cable’s insulation to expose the copper cable beneath. For household cables, you will reveal the earth, live and neutral.

Once the copper is exposed, make sure it is clean and snipped neatly without stray wires.

Before installing components of the joint or termination.

If your cable has a conductive screen, ensure it’s free from dirt and debris. If you clean the outer insulation sheath, wipe towards the open end of the cable.

When should you use a straight-through cable?

When working with electricity cable, terminations that are not solid and the impedance does not match when terminating with like for like cables.

However, in the case of running data cables, the cable should always be one piece or a straight-through cable to avoid signal interference and signal corruption for other EMF emitting infrastructure.

What is the most commonly used method of wire termination?

Crimping is commonly used for cable termination. It’s the most efficient way of getting through a volume of cables that need termination.

Why is it critical to follow termination standards?

If you are running communication cables in a data centre or office block, there must be a common standard that the installer works to.

Cables need to be defined by standard colours and diameters for easy identification. Working to standards helps to reduce the installation time and reduce installation costs.

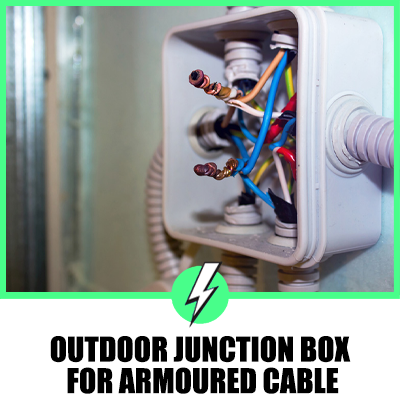

What is the difference between indoor and outdoor termination?

Its straightforward, outdoor kits provide greater cable protection from UV light and the elements in general.

If you work in a country where the sunlight is a constant headache in degrading insulation, the need for insulation that can repel or dissipate the UV rays is essential.

The problem has decreased over the recent years with the use of more direct data links rather than using a cable to span 100s of metres.

What is cable laying and termination?

Communication cables and electricity caves are frequently run underground or in trenches in protective conduit.

A selection of termination methods are incorporated for terminating the cables, such as clamps, saddles and spacers with termination or straight joints.

Which type of wiring is best for underground cables?

Copper in general, but the further you run a cable, the more the resistance builds, so choosing the correct cable is essential to a successful outcome.

What is XLPE cable?

XPLE is an acronym that describes the type of insulation cross-linked polyethene cable.

XPLE has some unique properties, such as a 3D molecular structure and shape memory characteristics.

When should I use XLPE?

Because of the unique structure of XLPE and the tightness of the molecular bonds the XLPE is perfect for the following:

- High voltage electricity insulation

- XLPE is extremely resilient to abrasion and stress fracturing

- Extreme temperature fluctuations

- Water and other liquids

- When dealing with chemicals or hazardous materials

Can XLPE cable be buried?

Yes, the XPLE is suitable for direct placement under the soil. Its structure is perfect for underground use without using a conduit.

The power should not exceed 600 volts for safe working use.

How would you check if the cable you made is functional?

You will need an ethernet cable tester. The ethernet cable tester has some cool features, such as checking each conductor in sequence.

The tester comes in two parts. You have a battery unit that you plug your ethernet cable into and a receiving end to plug the other end of the ethernet cable into.

Once the test starts, you should see 8 green lights illuminate in sequence and simultaneously with either side of the tester.

If the lights are out of sequence, you can see which conductor gives you the problem.

What causes cable problems?

There is rarely one reason only for a cable to become problematic. Sheathing degrades overtime throughout the cable, causing earth leakage or signal corruption.

Extreme temperature fluctuations damaged cables, and UV light causes the insulation to perish and become brittle.

Weather conditions, in general, are a cause of faulty cables with water ingress. Abrasion to the insulation causes cables to lose their protective sheathing.

There are several reasons why the sheathing material may degrade, including

How do I know if my cable is broken?

Connect your tester or a multimeter and perform a continuity test, if the cable is broken, you will not hear the buzzer, and nothing will show on the screen.

Without a full circuit, your appliance or router will not work, which indicates you have a problem.